We created a service to monitor the operational status of the chemical plants involved in production of a major industrial commodity, at numerous sites around the world.

We designed an innovative monitoring scheme that used a number of features relevant to the production process, from a variety of data sources. This allowed us to identify the status of processing lines around the world in a reliable, timely and cost-effective manner.

We gathered a range of archive data at Very High Resolution (<1m) to baseline the model. We then designed a protocol involving High Resolution (3-10m) data to allow an adequate revisit rate and optimised cost.

For new sites we also gathered fortnightly Very High Resolution (1m) to monitor start-up activities.

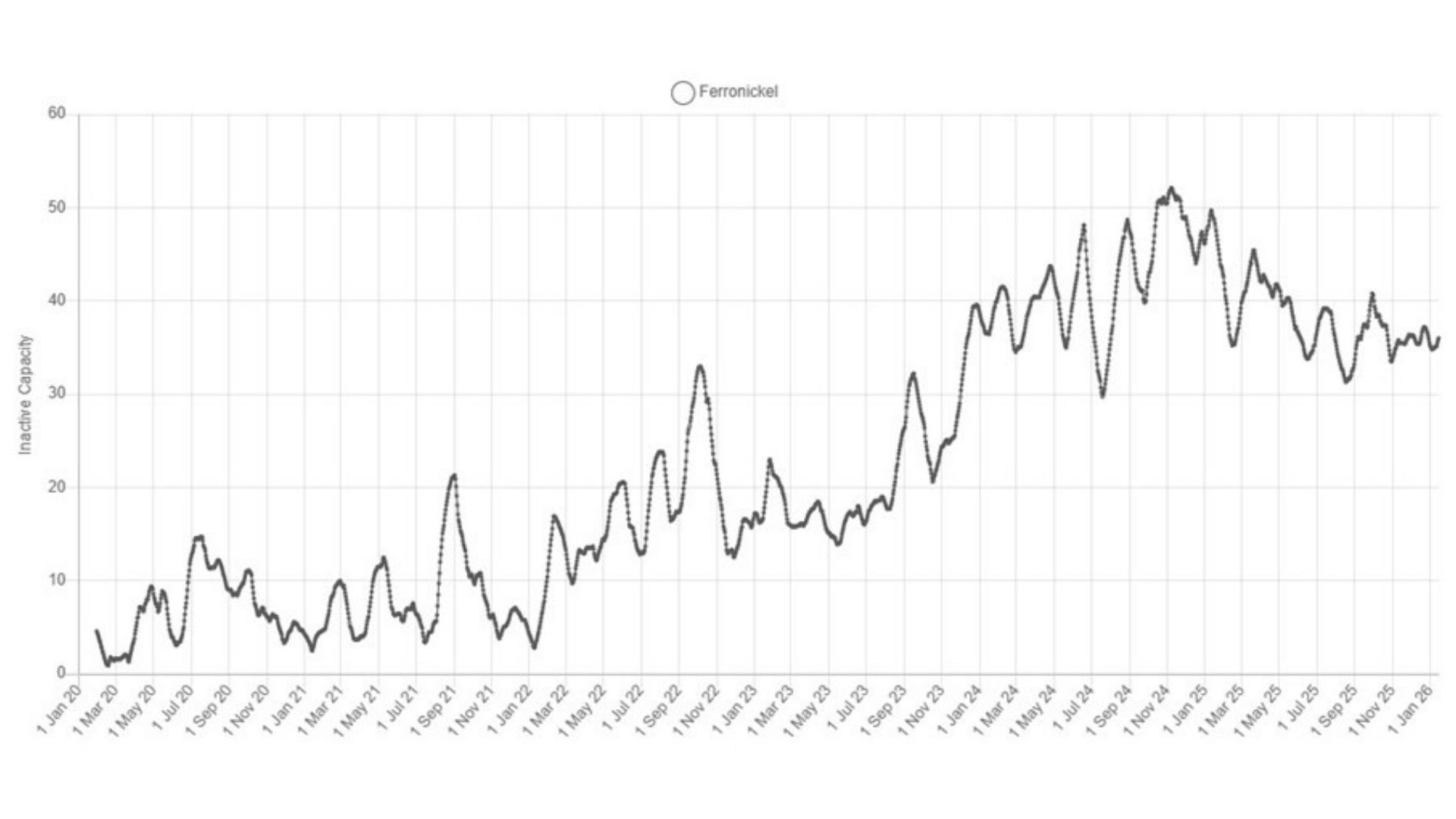

We presented the data in a similar fashion to our market-leading SAVANT service, allowing business users to see operational status clearly, quickly and simply. The outputs included operational status (operational / non-operational) and dispersion index (how active a site is compared to the usually-observed level of activity at the site).