Copper has been one of our most important metals since humans first discovered how to extract it from rocks some 7,000 years ago. The soft metal was used to make arrow tips and decorative objects, but when it was mixed with arsenic and then tin a strong new alloy was formed – and we moved from the Stone Age to the Bronze Age.

Now in the frenzy of the Information Age, copper is more important than ever. It is indestructible, malleable, endlessly recyclable and, of course, a superb electrical conductor that is at the heart of devices from iPhones to electric vehicles.

Demand for copper is higher than it has ever been, and it has become a vital part of the global economy. Disruption to the copper supply chain can have serious financial consequences, while changes in levels of demand can be an indicator of the economic health of a country or region. It is therefore important to monitor it as accurately as possible.

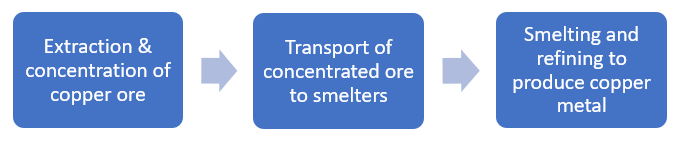

At risk of gross over-simplification, there are 3 key stages in the copper supply chain:

Earth-i can observe and measure the extraction of copper from vast open cast mines around the world, deriving detailed production data from very high-resolution 3-dimensional models of mines. However, feedback from our customers suggested that there was a real shortage of reliable data about the other end of the supply chain: smelting of copper ore to extract the metal.

Copper smelters are distributed around the world and are often found in very remote locations. Many of them are in countries which are experiencing rapid growth, particularly China where industrial modernisation, electrification and increasing prosperity is driving a rapidly growing demand for copper. Reliable information about the operational status of copper smelters can be very difficult to obtain, and when information is available it can often be weeks out of date.

Satellite monitoring provides the perfect solution to this challenge. Earth-i’s SAVANT service uses a number of satellite sensors to monitor smelters around the world. We collect images every day of smelter sites around the world, and have developed Artificial Intelligence algorithms to determine which smelters are active. Working with key customers and industry experts, these algorithms have been optimised and we can now reliably detect any disruption to normal smelter operations.

Earth-i is monitoring up to 90% of global smelter capacity and offers global and regional copper smelting indices, updated daily, as part of our SAVANT service. SAVANT’s algorithms differentiate between genuine shutdown of a smelter against any short hiatus in activity. Smelter restarts are typically detected within 1-3 days.

In the coming months, the techniques that have been used to monitor copper smelters will be applied to other important metals, bringing transparency to processes that have long been opaque and replacing unreliable and subjective reporting with consistent, objective measurements.

In our next blog Earth-i’s partner, Marex Spectron, will explore the importance of the Global Copper Smelting Index for financial markets. In the meantime, you can sign up for the free SAVANT service at https://savant.earthi.world/signUp.

Earth Observation specialist brings over 25 years technology and applications experience to company offering daily high-resolution imaging and data…